Industrial tray cable solutions according to international standards energy and power wire need to be flexible, resistant to bending, abrasion, oil, fold, flame retardant, corrosion (resistant to complex chemical environments such as weak acids and alkalis) so that the cable's advantages in drag chain systems and other industrial sites can be fully utilized. The continuous improvement of cable design and the use of imported materials have greatly improved the durability of the cable, and the advanced manufacturing equipment ensures the precise manufacturing process of the cable. Flexible cables have good mechanical properties and are highly flexible. When used in drag chains, the designed service life is 8 million cycles of bending, and it has been effectively verified in actual use.

Industrial tray cable solutions according to international standards energy and power wire need to be flexible, resistant to bending, abrasion, oil, fold, flame retardant, corrosion (resistant to complex chemical environments such as weak acids and alkalis) so that the cable's advantages in drag chain systems and other industrial sites can be fully utilized. The continuous improvement of cable design and the use of imported materials have greatly improved the durability of the cable, and the advanced manufacturing equipment ensures the precise manufacturing process of the cable. Flexible cables have good mechanical properties and are highly flexible. When used in drag chains, the designed service life is 8 million cycles of bending, and it has been effectively verified in actual use.

Application Of Industrial Tray Cable Solutions According to International Standards Energy and Power Wire

Industrial automation flexible cables are highly bent, bent, oily, frequent friction with the drag chain, high-frequency continuous reciprocating motion, etc., such as: drag chain systems, towing systems, mobile drive systems, industrial automation systems, etc.

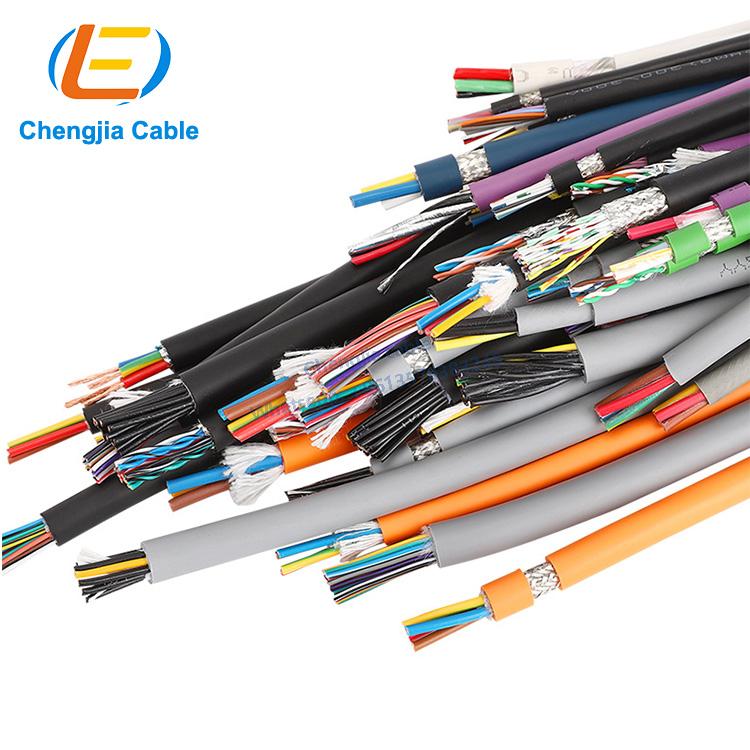

Industrial Tray Cable Structure

Conductor: multiple strands of ultra-fine finely stranded oxygen-free copper wire, in line with VDE0295class6 standard Insulation: high-strength polymer special composite insulation material

Core wire color: digital label or color distinction (can be produced or customized according to customer requirements) Inner sheath: special material for high-strength polymer special composite sheath

Shielding: anti-oxidation tinned copper mesh braided shield, weaving density ≥85%, can effectively prevent interference and attenuation of various signals. Outer sheath: special high-strength polymer special composite sheath material or imported PUR polyurethane material

Sheath color: gray, black, orange (other colors can be customized according to customer requirements)

Rated voltage: ≥0.5mm: 300/500V

<0.5mm: 300/300v

Test voltage: 2500V

Temperature range: -22C to +90C or -40°C to +105°C Bending radius:

Fixed installation: 5× outer diameter of cable Mobile installation: 7× outer diameter of cable

Chengjia Mobile Bending Test Standard:

1.Simulate the bending and movement of the cable in the drag chain to test various conditions. Take a sample from the finished product and fix it on the drag chain experimental device according to the method below. The bending radius r=7.5D; S=600mm speed is performed at 60 times/min. test. The number of round trips exceeds 5,000,000 times without disconnection.

Chengjia mobile winding test standard:

2. Take a sample from the finished product, and fix the moving pulley and weight as shown in the figure below. The diameter of the pulley and the weight of the weight refer to UL standards. The moving pulley is tested at a speed of 0.33m/s and a moving distance of 0.5m or more. Pulley Sample Pulley The number of round trips exceeds 20,000 times. No short circuit occurs, and the insulating sheath is not cracked or damaged.

Chengjia 90° bend test standard:

3.Take a sample from the finished product, fix it on the 90 bending test device as shown in the figure below, and hang a specified weight at the other end; the bending radius and weight of the weight refer to UL standards, and the device is bent at a speed of 40 times per minute for testing. No short circuit occurs when the number of round trips exceeds 50,000 times, and the insulating sheath is not cracked or damaged.

Contact: Mandy Dai

Phone: +86-13570383245

E-mail: sales@flex-cables.com

Whatsapp:0086-13570383245

Add: No. 12 building, No.46,Shilou Section,Shilian Road, Panyu District,Guangzhou, Guangdong,China

We chat